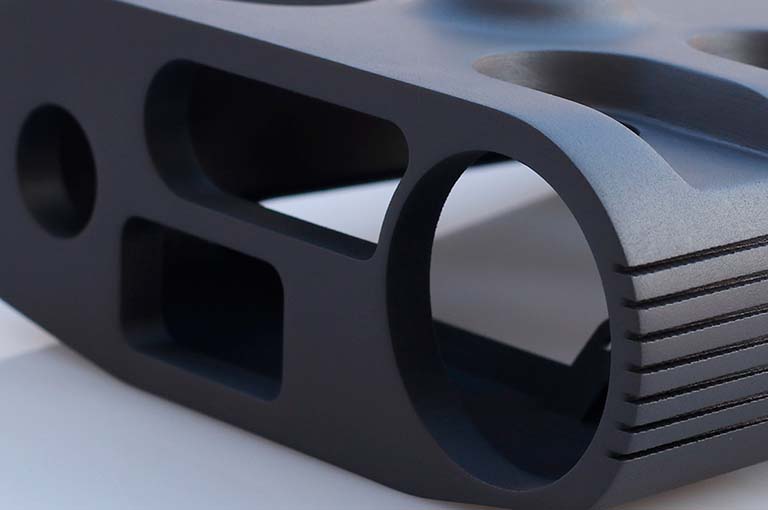

CREATE MORE efficient parts with

high grade 3d printing service

Manufacture functional components and parts withstanding frequent and intensive use

A range of flawless SLS materials that guarantee the highest level of performances, engineered by experts with full knowledge on demanding applications, and a person-to-person 3D printing service ready to satisfy your project requirements.

Why Windform 3D printing composites are different

Production grade

Windform 3d printing composites provide for the manufacturing of functional components and parts withstanding frequent and intensive use.

Born to be strong

Create 3D-PBF parts so strong, light, durable and flexible to replace metal in most demanding sectors.

Quality that wins the proof of time and space

Windform materials are validated by NASA, ESA, JAXA as they enhance applications that require highest fidelity, small sections, and lightweight.

Resistant to Vibration & extreme temperatures

Windform composites withstand shocks, high vibrations and various range of temperatures.

Optimal density for a minimum weight

Key for the production of complex components where lightness and strength coexist for increased performances.

Flame retardant

Windform range offers flame retardant composites whose high strength, stiffness and lightweight make them ideal for avionics, aerospace, automotive, consumer goods and electronics.